Southfield’s Community Appearance Director, Tyrice Beeks, is calling on commercial enterprises to comply with the city’s Keep Southfield Beautiful! efforts. Community Appearance is a facet of the Code Enforcement Department. Each spring, the owners and managers of businesses, restaurants, gasoline stations and car repair facilities are reminded of applicable beautification regulations to enhance curb appeal in the city.

“A passerby’s first impression of your property may be a lasting impression of Southfield,” Beeks says. “By following these regulations, you will be doing your part and fulfilling your responsibility to Keep Southfield Beautiful! If we all do our part, we can make a difference.”

Regulations affect all aspects of outdoor commercial areas, specifically: Parking Lots, Dumpsters, Landscaping, Outside Storage, Buildings and Signage/Displays. There is an explicit list of code requirements for each category of enterprise – businesses, restaurants, gas stations/car repair – although there are similarities among the lists.

Beeks says many businesses follow city beautification regulations. However, to assure widespread compliance, all properties will be inspected by the Code Enforcement Department. “It is our hope that any deficiencies you find will be addressed before an inspector visits your site,” Beeks says. “Businesses found to be continuously in violation will be issued a citation or fines.”

To review the complete list of regulations by category, follow the links below:

[vc_separator]

BUSINESSES

Parking Lots

- Striping – parking spaces must be double striped. You will be asked to restripe your lot if it is only single striped

- Sealing – surface should be uniform in nature

- Patching of holes and cracks

- Resurfacing when needed

- Bumper blocks place properly and not broken

Dumpsters

- Properly enclosed and spaced on site according to site plan

- Enclosure well maintained

- Free of litter and debris

Landscaping

- Replacement of dead or dying trees/shrubs and other plant material

- Landscape beds and right of way free of weeds and litter

- Adequate wood chips

- Grass cut and well maintained

Outside Storage

- Items may not be stored outsides except in approved, designate industrial zoned areas of the City

- No storage of pallets

- No storage of vehicles

Building

- No peeling paint

- No broken/cracked glass

- Gutters/downspouts well maintained

- Awnings well maintained

Signage

- Well maintained

[vc_separator]

RESTAURANTS

- Dumpster lids must be kept closed to decrease the chance of blowing litter. Please make sure your staff breaks down boxes before placing in the dumpster.

- The area around the dumpster and enclosure must be kept free of litter and debris. Nothing should be placed outside of the dumpster.

- Other trash receptacles on your property must be emptied frequently to avoid overflowing litter from customers.

- The parking lot, grass and landscape areas must be kept weed, litter, and debris free. This includes any right of way area. Please have a daily staff schedule for the removal of litter and debris on your property.

[vc_separator]

GASOLINE STATIONS AND CAR REPAIR FACILITIES

- Property must be in compliance with your approved site plan and perpetual maintenance agreement.

- No parking of damaged motor vehicles except on a temporary basis for seventy-two (72) hours or less.

- Junk parts and junk vehicles shall not be kept on the outside of the building.

- No outside storage or display of any kind except for the display of new merchandise related to the primary use of a gasoline stations for retail sale during the hours of operation of the gasoline station (for example, no selling of wood chips, plants, etc.).

- No storage or display of any kind in the street right of way area

- Tow trucks must be parked only in designated areas and are not permitted in the corner clearance area.

- All vehicles must be parked in designated parking areas and not double parked.

- Unlicensed vehicles or vehicles for sale are not permitted.

- Dumpster lids must be kept closed to decrease the chance of blowing litter. Please make sure your staff breaks down boxes before placing in the dumpster.

- The area around the dumpster and enclosure must be kept free of litter and debris. Nothing should be placed outside of the dumpster.

- Other trash receptacles on your property must be emptied frequently to avoid overflowing litter from customers.

- The property, grass and landscape areas must be well maintained and kept weed, litter, and debris free. This includes any right of way area.

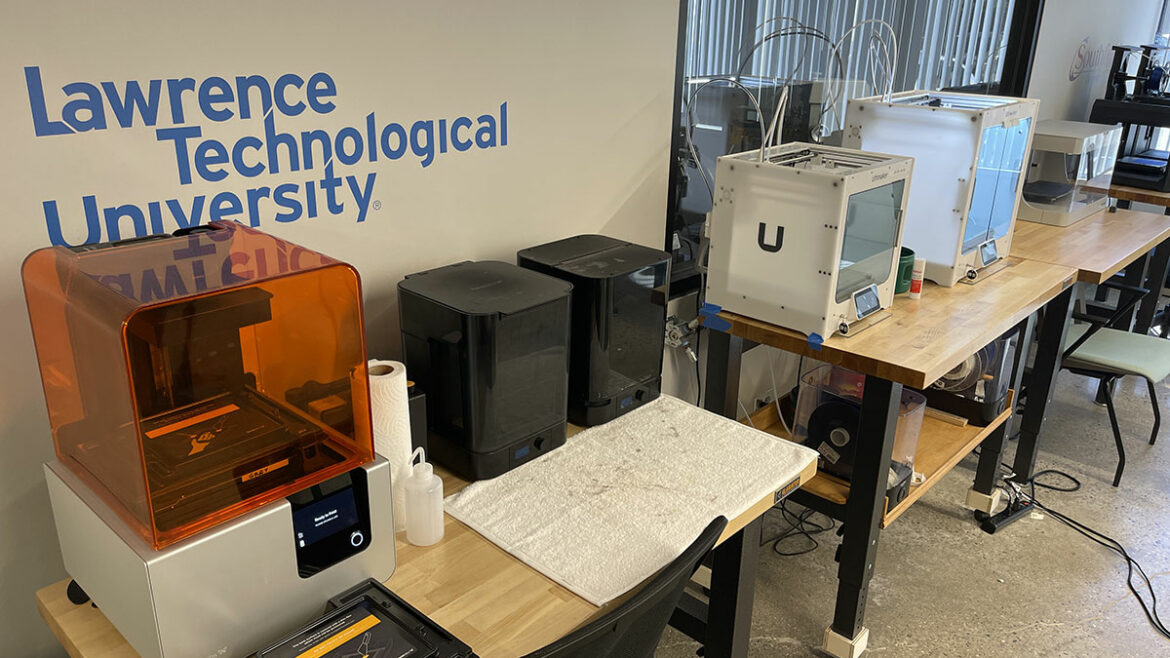

The Centrepolis Accelerator at Lawrence Technological University has been named a winner in this year’s Growth Accelerator Fund Competition, conducted by the U.S. Small Business Administration’s Office of Innovation and Technology.

The Centrepolis Accelerator at Lawrence Technological University has been named a winner in this year’s Growth Accelerator Fund Competition, conducted by the U.S. Small Business Administration’s Office of Innovation and Technology.

SOUTHFIELD—Lawrence Technological University has been named the No. 3 automotive engineering university in the nation, according to College Gazette, a college ranking website.

SOUTHFIELD—Lawrence Technological University has been named the No. 3 automotive engineering university in the nation, according to College Gazette, a college ranking website.

The partnership will support new and existing programs for venture acceleration of energy hardware startups in the Midwest. The partners plan to support more than 360 startups and small businesses via the tailored programs, which include both virtual and in-person events, sector-specific curricula, mentorship, prototyping resources, and connections with industry. Beneficiaries of the program will be a diverse array of founders from across the region, including those from universities, low-income communities, and urban areas.

The partnership will support new and existing programs for venture acceleration of energy hardware startups in the Midwest. The partners plan to support more than 360 startups and small businesses via the tailored programs, which include both virtual and in-person events, sector-specific curricula, mentorship, prototyping resources, and connections with industry. Beneficiaries of the program will be a diverse array of founders from across the region, including those from universities, low-income communities, and urban areas.

The university’s computer science program has turned the two-seat car into a second autonomous vehicle research platform for students to learn to develop software for the self-driving cars of the future.

The university’s computer science program has turned the two-seat car into a second autonomous vehicle research platform for students to learn to develop software for the self-driving cars of the future.